Creation & Usage of Custom Wire Baskets for Aviation Parts

The F-35 fighter jet’s exterior body panels are held in place by tens of thousands of screws in hundreds of different shapes and sizes. Before they can be used in the assembly of the airframe, each screw must be cleaned and coated with a chemical primer — a delicate process that requires the various fasteners to remain in place and organized throughout. The assembly plant developed a cell to “kit” the various fasteners as needed by production, and asked Three M Tool to develop a custom wire basket system to keep the kitted fasteners organized through the process.

The Challenge: Kitted Aviation Fasteners & Automated Processes

Three M Tool was tasked with creating a basket system of 125 small wire baskets that would keep the different types of fasteners separate and organized during the cleaning and coating process. The client required the basket system to move securely through a multi-tank automated cleaning and chemical coating line without slowing or disrupting the process or jostling the fasteners.Our Solution: Custom Made Wire Baskets & Trays for Aviation Parts Cleaning

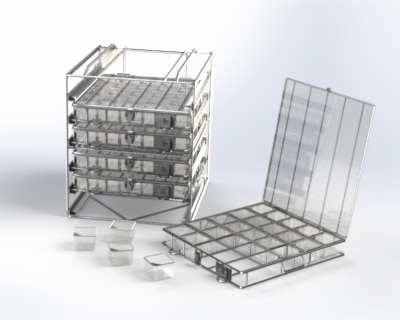

Three M Tool designed and built a system of insert baskets and carrier trays to organize and hold 25 insert baskets, plus a carrier rack to securely transport five carrier trays through the automated process. The 3”x 3”x 2” insert baskets featured an ⅛” diameter top frame and a formed bowl of 6 mesh x.035 woven wire with .132” openings. These baskets used 304 stainless steel construction throughout, and all surfaces were coated in Gray Halar (7-10 millimeters thick) after fabrication for additional part protection. The corresponding carrier trays (18 5/16”x 16” x 7/16”) were also constructed in 304 stainless steel, with electropolishing after fabrication. They featured a ¼” diameter rod frame of crossing grid rods to securely support the insert baskets. The hinged lids with compression latches provided additional security. Finally, the carrier rack (18 13/16” x 17 1/16″ x 10 9/32”) was constructed of a 5/16″ diameter 304 stainless steel rod frame with support rods and a conveyor bottom. Two 3/8″ diameter top-mounted handles with 2.5″ clearance were designed for ease of transport. The design included bent hooks on each level to prevent backward insertion of the carrier trays. 16 gauge sheet metal supports with laser-cut holes provided optimal drainage. All surfaces were coated in Gray Halar (7-10 millimeters thick) after fabrication to match the insert baskets.The Outcome: Secure Wire Baskets That Stand Up to Automation

With over 75 years experience in metal fabrication for a wide array of industries and applications including aerospace, aviation and defense, Three M Tool was the ideal design and manufacturing partner for this client. Our team applied our significant expertise creating part-specific custom wire baskets for applications like cleaning and coating to the challenge presented by the client, leading to a successful final product. As we approached this project, we were aware that even the smallest flaw in the kitted fasteners could result in disaster. Each fastener would have to be cleaned and coated— even in the tiniest, hardest-to-reach areas — to perfection without inflicting any damage. Our final basket, tray and carrier designs ensured complete, comprehensive cleaning and coating while also protecting the fasteners from damage that could otherwise occur during the processes.Custom Made Wire Baskets for the Aviation Industry

In the aerospace and aviation industry, one-size-fits-all solutions are as ineffective as they are potentially hazardous. At Three M Tool, we excel at creating custom made wire baskets for highly-specialized applications like aviation parts cleaning. If the challenges you’re facing require an out-of-the-box solution, the experienced Three M Tool team can design and manufacture a basket or basket system tailored to your specific needs. Contact our team to tell us more about your unique requirements and get a quote today!