Benefits of Custom Wire Baskets for Medical Parts Washing

At Three M Tool, we know that proper cleaning and sanitation is absolutely paramount to our clients in the medical and pharmaceutical industries. When the health and safety of patients and medical professionals are on the line, we pride ourselves on providing our clients peace of mind regarding the thorough sanitation of their medical instruments, parts, containers and tools.

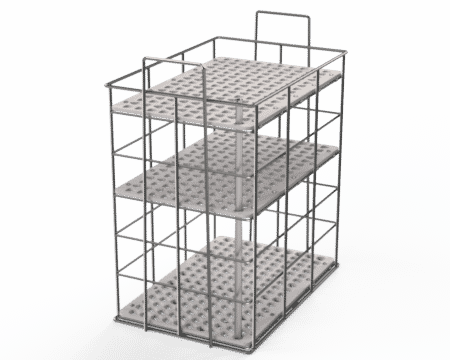

One such client, an East Coast medical device manufacturer, came to Three M Tool seeking a wire basket solution to hold small tubes used during laparoscopy, a type of minimally-invasive surgical procedure that allows surgeons to access the interna abdomen and pelvis without the need for large incisions. The custom solution in question would need to hold the tubes stable during cleaning and transportation.

As we approached this project, we knew that — as with any parts and tools used in surgical procedures — the comprehensive sanitation of the medical tubes was the primary concern. But this custom project was especially exciting for our team due to the client’s unusual requirements for the wire basket design itself. Read on to learn more about the design, development and manufacturing of this custom wire basket for medical parts washing.

The Challenge: Stainless Steel Parts Cleaning Baskets — With No Metal-to-Metal Contact?

Three M Tool was asked to create a wire basket solution that could hold 200 stainless steel medical tubes securely through rigorous cleaning and transportation processes, namely nitric passivation and aqueous cleaning, robotic loading and unloading, Scotch-Brite™ treatment, and transportation.

But this client’s request came with a unique — and challenging — requirement: The medical tubes contained by the custom basket solution could not have metal to metal contact. The basket also had to drain properly and thoroughly, leaving no watermarks or scratches from processing on the tubes. The project would be considered a success if the tubes cleared the cleaning process with minimal or no markings while also achieving optimal throughput.

Our Solution: Custom Industrial Stainless Steel Basket for Medical Parts Cleaning

We were excited to tackle this interesting project, as we knew our custom wire basket design and engineering expertise was perfectly suited to help our client find an effective solution. Wire baskets offer many benefits when used in applications like medical parts washing and sanitizing; the open spaces offered by wire mesh allow for unblocked flow of air, liquid or ultrasonic waves around the parts, and the basket’s capacity, materials and finishes can all be customized to ensure both the basket and the parts withstand the cleaning process without sustaining damage. A custom wire basket was the clear solution for this client, and the Three M Tool team was eager to dig into the design challenge posed by the restriction against metal-to-metal contact.

Our engineering team began the custom wire basket design and manufacturing process by assessing the physical parts’ required dimensions and delivered an initial prototype design to the customer for their evaluation. We then collaborated with the customer to refine the design, answering their questions and resolving any potential issues before generating a physical prototype for the customer to test.

“Three M has been instrumental in supporting new process development for our cleaning and finishing operations…and has responded to our needs quickly and has supported us after the initial order has been completed. They always deliver a well made and well designed product. Customer service has been excellent.”

The final custom wire basket design separated the stainless steel tubes without metal-to-metal contact by using panels made of chlorinated polyvinyl chloride (CPVC) thermoplastic. CPVC can withstand higher temperatures than non-chlorine treated PVC plastic, making it an ideal material choice for medical parts cleaning and sanitation applications.

The Three M Tool team also devised a special configuration for the opening shapes in the grids that allowed the client’s robot to sense the part position and location within the basket solution, preventing witness markings. Each of the panels were fixtured and CNC milled for precise tolerances.

The Outcome: An Innovative Solution to Sterilize Medical Equipment

Upon delivery of the finished custom basket solution, the medical device manufacturer was pleased with the “well-made and well-designed” product. A senior manufacturing engineer on the client’s team remarked that Three M Tool’s solutions have “been instrumental in supporting new process development for [their] cleaning and finishing operations.” The engineer also noted that Three M Tool’s customer service and support was prompt and excellent throughout the entire process and beyond order completion.