Wire Mesh Baskets for Coating, Finishing & Impregnation

Coating, Finishing & Impregnation Baskets

Improve the efficiency and effectiveness of your passivation, dipping or drying processes with high-quality wire mesh baskets from Three M Tool.

Custom Wire Baskets for Coating

Three M Tool designs and manufactures wire mesh baskets for use in coating, finishing and impregnation processes. Our industry experience enables us to recommend the right material and features for your unique application, resulting in a custom basket that will withstand the rigors of your treatment processes while ensuring even coating and drying.

Use Cases

Our versatile wire baskets for coating, finishing and impregnation have been used in a wide variety of industries. You’ll find Three M Tool custom coating and finishing baskets serving industries including:

- Automotive

- Aviation & Aerospace

- General Manufacturing

- Industrial Manufacturing

Features

Our design and manufacturing process allows us to offer many standard and custom features and additional services as required by your application. We frequently manufacture unique lids and dividers to keep components secure during coating and finishing processes and transport. We have also designed and implemented new grid configurations, specialized welding processes, and other innovations to meet our customers’ needs.

Materials We Use

Selecting a base material for a wire basket design is a balancing act between material characteristics: Weight vs. strength, cost vs. corrosion resistance, etc. We strive to optimize performance by understanding each material’s strengths and weaknesses to choose the best material for each application. Below is an overview of our most commonly-used materials and their recommended usages:

304 Stainless Steel

The most common of the industrial stainless steel grades, 304 stainless steel is readily available in a wide variety of shapes and sizes and is relatively easy to form and weld. Good for high-temperature applications (up to 1200° F,) wet and mildly caustic environments. Can be powder coated for added part protection. Electropolishing is recommended for all ultrasonic applications.

316 Stainless Steel

Slightly stronger than 304 stainless, with better corrosion resistance and better high temperature strength, 316 stainless steel is readily available in most shapes. Compared to 304, it is still relatively easy to form and weld. Good for high-temperature applications (up to 1600° F,) salt water environments, and acidic and alkaline environments. Can be powder coated for added part protection. Electropolishing is recommended for all ultrasonic applications.

330 Stainless Steel

Better high-temperature strength than both 304 and 316 stainless (up to 2200° F.) Limited selection of shapes available. Higher nickel content makes it more difficult to form and weld. Good corrosion resistance in acidic and alkaline environments. These qualities also apply to other high nickel-content alloys.

Carbon Steel

Also called mild steel, carbon steel is strong, inexpensive, easy to form and weld, and readily available in a wide variety of shapes and sizes. Carbon steel is a great choice for manual solvent cleaning, oil dipping, and indoor material handling applications. It offers very limited corrosion resistance in its natural finish, and is therefore generally not recommended for wet locations, acidic and alkaline environments, or ultrasonic or aqueous cleaning applications.

Our Work

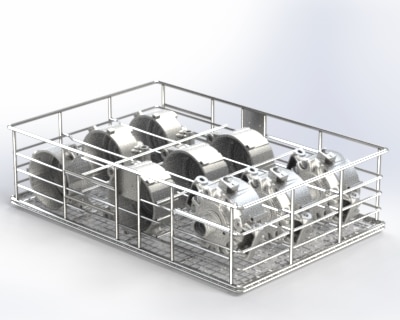

Custom Wire Basket For Oddly Shaped Parts

Our customer needed a custom stainless steel wire basket to hold cast aluminum parts through a vacuum impregnation process that cleans the parts, coats them, spins at several hundred RPMs to remove excess sealant, and finally cures them.

Let’s talk about your needs.

The expert TMT team will consult with you about your unique application and recommend the best wire basket solution.