WIRE MESH BASKETS FOR PARTS CLEANING & WASHING

Custom Parts Cleaning Baskets

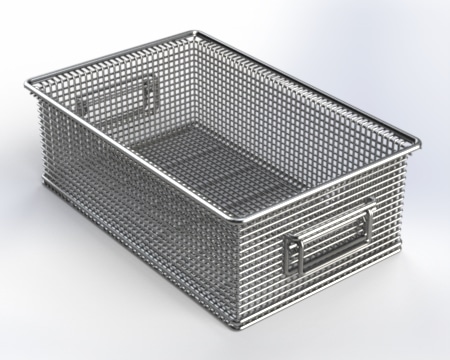

Custom Wire Baskets for Parts Cleaning

Use Cases

- Aviation

- General Manufacturing

- Medical/Medical Device Manufacturing

Features

Materials We Use

304 Stainless Steel

316 Stainless Steel

330 Stainless Steel

Carbon Steel

Our Work

Heavy Duty Wire Baskets for Precision Cleaning

We created a US-manufactured equivalent of a European-style precision cleaning basket. The European-style baskets are rugged yet extremely smooth, with large openings to effectively clean all types of manufactured parts.

Parts Cleaning Basket for Parts Washing Station

Our customer needed a durable wire mesh parts cleaning basket that would stand up to the rigors of constant industrial parts washing and have rigid loop handles for easy part agitation.

Grit Blaster Wire Mesh Reclaimer Screen

Our customer manufacturers enclosed grit blasting (sand blasting) booths. They needed a reclaimer screen that would offer durability and precise filtration at a price point that made sense for a “semi-consumable” product.

FAQ

Before deciding what material to use, we first need to determine which mesh construction will work best for you. There are two constructions: welded and woven.

Welded Wire Mesh: Cross wires are laid on top of long wires and are resistance welded together at each intersection creating very even square openings.

- Welded mesh usually has larger opening sizes

- Welded creates one even surface size, as all wires are straight and on the same plane

- Welded can have heavier wire gauge and typically the more rigid mesh option

Woven Wire Mesh: Wires are woven, over-under-over-under, to create the mesh.

- Woven is much more flexible

- Woven is great for one-piece construction of pans, bowls, or frame-less baskets

- Its woven construction creates a bumpy surface feel but allows for smaller openings.

A good rule is to start by looking for an Opening Size that will properly contain your parts, then search for the largest Open Percentage near or slightly smaller than that opening size, keeping an eye on the wire diameters of the mesh (larger is stronger but heavier)

- Opening Size: This is the approximate size of the square hole between the mesh wires. The opening size should be slightly smaller than the smallest part dimension. Obviously, if the mesh opening size is bigger than the parts, the parts will poke thru or fall out. On the other hand, if the mesh opening size is needlessly small, flow thru the basket will be diminished.

- Open Space Percentage: Wire mesh is used to keep something on one side while letting something else flow thru. Open Percentage measures the portion of surface area that is open, not blocked by the wires. The higher the Open Percentage, the better the flow. In general, wire mesh is more open that perforate metal for the same opening size (because the wires between the holes are thinner than the web in perforated metal)

- Wire Mesh Size Designations: Let’s take a deeper look at the effects of the mesh construction.

- Design Effects of Mesh Number (wires per inch): The Mesh Number describes how close the wires are to each other. A higher Mesh Number means the wires are tighter together, the Opening Size is smaller and the Open Percentage is lower (assuming the same wire diameter). Tightly spaced wires (higher Mesh Number) using large diameter wires creates a mesh that is extremely rigid and heavy, but expensive and difficult to work with. The opposite is also not desirable. Widely spaced wires (lower Mesh Number) using small diameter wires creates a mesh that can be difficult to work with because it’s too flimsy and the wires shift within the weave.

- Design Effects of Wire Diameter: The diameter of the wire used in the mesh contributes to the strength, rigidity, and weight of the mesh. Large diameter wires (over 0.080″) make very strong mesh but can make a basket very heavy. Smaller diameter wires (under 0.020″) are light and very easy to work with, but can tear easily if parts are heavy with sharp corners or points.

Let’s talk about your needs.