Wire Basket Linings

Wire Mesh, Perforated Metal, and Expanded Metal

Most wire baskets are lined with either woven wire mesh, welded wire mesh, expanded metal, or perforated steel. Each wire basket lining material has distinct advantages and disadvantages.

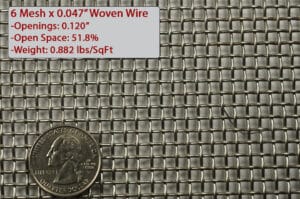

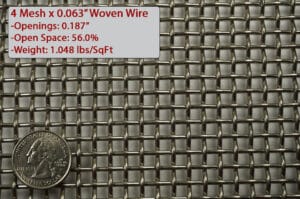

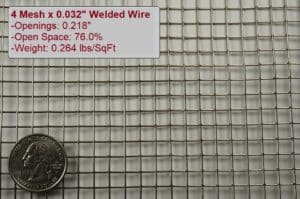

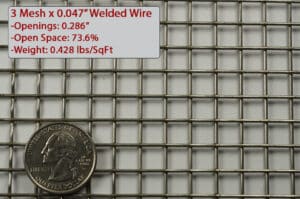

Wire Mesh

Wire Mesh is designated by a “Mesh Number” (number of wires per inch) and a “Wire Diameter” (the diameter of each wire). The opening size is approximately 1/(Mesh Number) minus (Wire Diameter).

- Welded Wire Mesh: Cross wires are laid on top of long wires and are resistance welded together at each intersection creating very even square openings. Welded mesh is more rigid (less flexible) than woven wire mesh. Typical welded wire mesh is 6 mesh or larger, and is .047” diameter wire or greater.

- Woven Wire Mesh: Wires are woven, over-under-over-under, to create mesh that is more flexible than welded mesh. This flexibility allows woven mesh to be formed into one-piece bowls or pans. There is also an almost unlimited selection of woven wire mesh sizes and wire diameters.

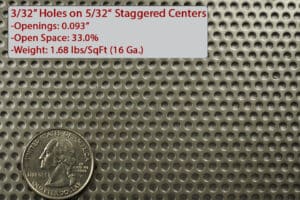

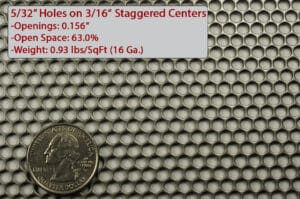

Perforated Metal

Perforated Metal is solid sheet metal with typically round holes punched in even rows. Hole diameters are rarely smaller than the material thickness. Perforated metals are designated by hole diameter, hole spacing, and material thickness. Readily available in carbon and 304 stainless steel, with limited sizes in other materials

This is the best lining choice for a very smooth surface, but typically has less open space than wire mesh or expanded metal.

Expanded Metal

Expanded Metal is solid sheet metal that is slit and pulled open (expanded) to create a sheet of diamond shaped openings. Designated by diamond size and material thickness. Expanded metal as an effective industrial basket lining should have supporting perimeter frames or protective U-edging on all exposed edges. Expanded metal is a low cost material, but quite often the added difficulties in basket fabrication will offset any material savings.

- Expanded Metal (standard): Very inexpensive material. The surface of the sheet is rough and the edges of the diamond-shaped holes have many sharp edges that should be considered in the design process.

- Flattened Expanded Metal (FEM): Standard expanded metal is rolled (“Flattened”) to create a smoother sheet with fewer burrs and sharp edges, although the diamond-shaped holes will still have some sharp edges that should be considered in the design process.

Need a quote?

We can deliver your quote with a drawing within one week and we deliver a same-day response to customer inquiries.